Case Detail

Optical Data Transmission Device

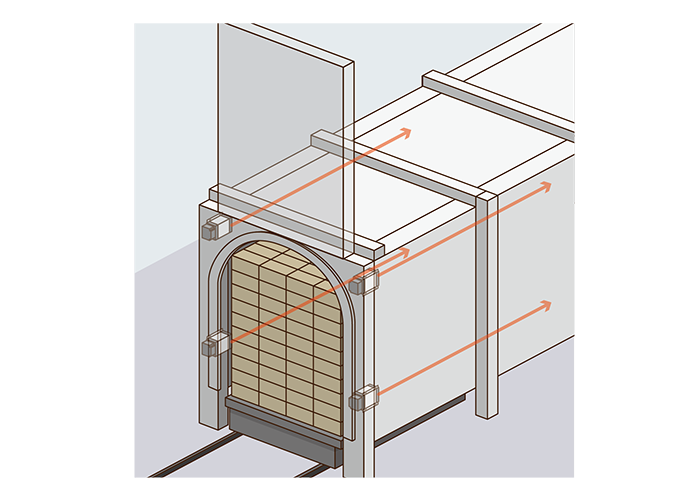

Load collapse detection in the furnace

Load collapse detection in the furnace

It detects load collapse in the firing furnace of the ceramic firing line.

Case Study

LiDAR was adopted to irradiate the firing furnace with a laser and measure the position where the load collapse occurred.

A normal photoelectric sensor could detect the presence or absence of a load collapse, but if the furnace is long, maintenance confirmation is required at all positions, and by using LiDAR, a maintenance opening is made only at the position where the load collapse occurred. Work efficiency has improved because it is only necessary to check.

A normal photoelectric sensor could detect the presence or absence of a load collapse, but if the furnace is long, maintenance confirmation is required at all positions, and by using LiDAR, a maintenance opening is made only at the position where the load collapse occurred. Work efficiency has improved because it is only necessary to check.

Product's Category

- Scanning Rangefinder

- Photoelectric Switch

- Sensor for Iron & Steel Industry

- Optical Data Transmission Device